Using local talent and local timber to fit customer needs

Using local talent and local timber to fit customer needs

Woods Run Forest Products' goal in 1978 was to produce lumber products that best fit the customer’s needs. That goal continues today.Our goals do not include being the biggest or the cheapest, but to always try to provide the best value, the best information, the most help with product selection, and the highest customer satisfaction. We are unwavering in our commitment to provide a product that lasts a long time in outdoor applications. But we also understand the need to protect our customer and the environment from hazardous exposures to chemicals. In staying true to both, we have resisted the rush to the new generation of treatment chemicals and lower retentions, because they do not perform to our expectations, nor provide the assurance of safety.

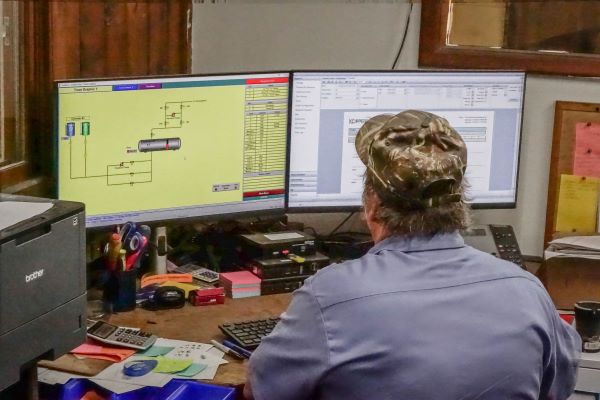

We have researched and tested every new chemistry the industry has proposed, using a miniaturized pressure treating plant we built specifically for trials of new chemicals. We currently use only chemicals that have survived the only true and reliable test of safety and performance, that is the test of time. We offer three different treatment options, each one has more than 20 years history of safe and effective use.

In the 40 years that we have been treating forest products we have seen many changes come and go. Treating chemistry, treating standards, and regulations have all changed dramatically and will continue to do so. With our experience in the past and our eyes to the future, we are well versed in the old and the new so we can help you select the best product and preservative for your needs.

If a better treatment comes along, or if one of the recent innovations prove itself to our satisfaction to be safe and effective, you can be assured we will be the first to know, and the first to offer it to our customers.

The history of Woods Forest Products can be traced back to 1970 when a college student on a summer trek thru the Rocky Mountain West became stranded with a blown up pickup engine in Franklin, Idaho. Needing to find work to earn a new engine, he applied at a logging operation and became introduced to, and enthralled with, the logging industry. While operating an old McCullough chain saw and a Caterpillar skidder up in the mountains above Poison Creek, he abandoned his old vision of becoming a college professor for the new dream of a lifetime of logging. He stayed on long after earning enough to repair his pickup, and surrounded by the whine of power saws, the clank of cat tracks and the crash of falling trees, he fleshed out a plan that became the roadmap to his future.

Four decades since those days on the Idaho mountaintop, Woods Run has stayed focused on the original vision: to produce the best forest products possible using local timber and local talent.

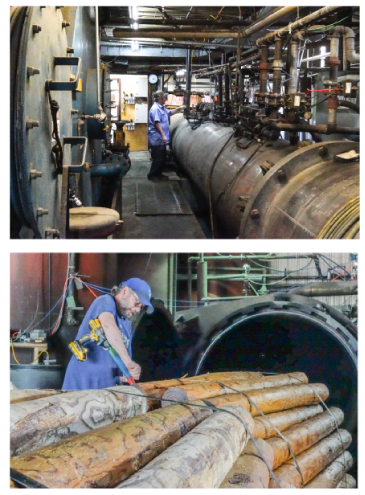

The combination of our sawmill, reman and treating capabilities allows us to offer specialized and highly unique products to fill customers individual needs. We have grown with the industry and with our local timber source, but we have stayed true to the original dream. Although we procure a significant portion of our lumber from Southern and Western mills, our first choice is always to work with local timber if it meets the customer’s needs.

At Woods Run we understand that our purpose as a treater is to produce long lasting lumber. We think that this core mission has been forgotten by many in our industry, who have become overwhelmed with the new regulations the industry has been grappling with since the end use restrictions were put on the use of CCA. Our treating plant has a clear focus on producing lumber products that last a long time , while complying with the constantly changing regulatory landscape. We maintain stringent quality control in our treating plant is to ensure that the products we treat are uniformly treated to assure a long service life.

We use state of the art X-ray fluorescence to analyze retentions, and color- shift indicators to test for penetration to ensure compliance with the customers chosen standard , which may be AWPA, or local or national building code, or it may be an standard unique to the individual customer’s needs or wishes. We contract Timber Product Inspections to oversee our quality control program, and they in turn are overseen by American Lumber Standards, who routinely inspects our plant and our production to ensure the quality of our treated wood. The customer can be assured, with this triple level of inspection, that the products they buy from us will perform as expected.